Bustruncking Flexible Power Distribution

Busbar Trunking System Installation Services

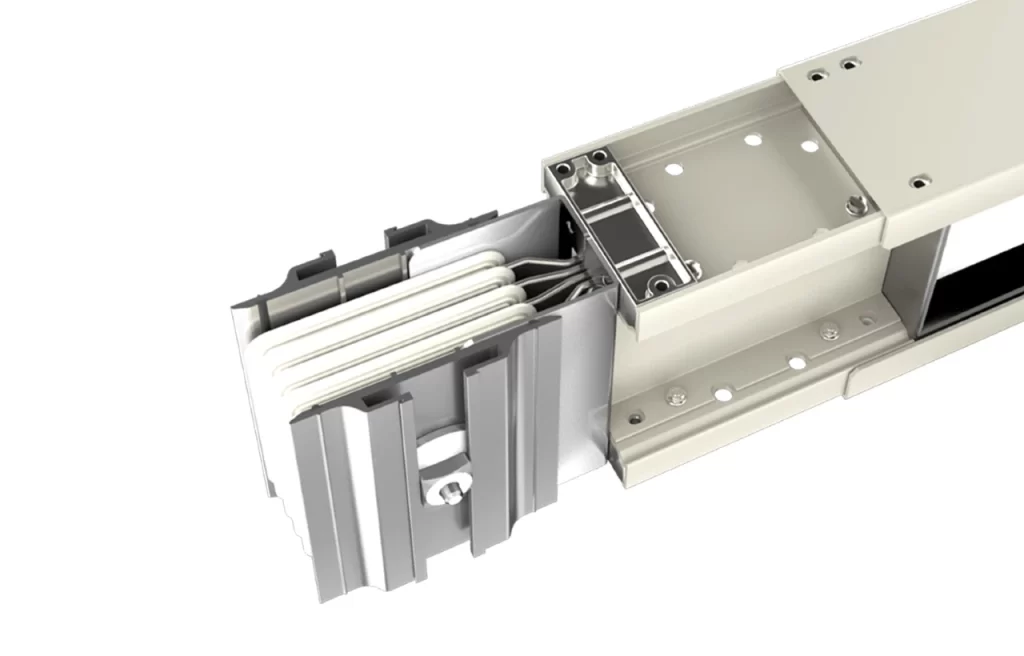

A busbar trunking system is a simple way to send electricity. It uses metal bars made of copper or aluminum inside a strong cover. This system is safe because it protects the wires from damage. Many buildings and factories use it to get electricity. It also saves time when setting up and makes fixing problems easier. For these reasons, many people choose busbar trunking for power.

Types of Busbar Trunking Systems

- Sandwich Bus Trunking (SB): Metal bars are put between covers for protection.

- Compact Air Bus Trunking (CB): Uses air spaces to keep the bars safe.

- Lighting Trunking (LB) – LV: Made for low-power lights.

- Track Busway (MB) – LV: Another low-power type.

Busbar trunking is useful because it is safe and easy to use. More people now choose it for sending electricity.

If you need help setting it up in India, many companies can do it. Experts can install and fix busbar trunking systems. Good installation helps the system work well and safely. Picking the right team means it will last longer and not break often. As a result, buildings and factories get steady power without problems.

In short, a busbar trunking system is a great way to send electricity safely and easily.

Let's Have A Talk

Contact Information

- Head Office :

- 174 B Meera Nagar, Bhuwana, Udaipur, Rajasthan 313001

- Phone No. +91 93525 23121

- Email : naresha@manikaran.net

Our Branches

- Mumbai Office :

- Office no. 502, White House CHS Road & Jp Road Junction, Andheri (West), Mumbai - 400 058

- Noida Office :

- Sec 62 - Green Boulevard 5th Floor, TOWER-C, Green Boulevard, Block B, Sector 62, Noida, (UP ) 201301

- Ahmedabad Office :

- Earth Arise 11th Floor, Earth Arise, Sarkhej - Gandhinagar Highway, Makarba, Ahmedabad, Gujarat 380015

The Story of Busbar Trunking Systems From The Past Till Now

The history of busbar trunking systems traces back to the mid-20th century, where they emerged as an efficient alternative to traditional cabling for electrical power distribution. Initially bulky and cumbersome, these systems have evolved over time to become more streamlined and adaptable to various needs. With advancements in technology and safety standards, busbar trunking has gained popularity worldwide.

Today, the global market for busbar trunking systems is booming, valued at over USD 2.6 billion in 2023 and expected to grow steadily. Its efficiency, cost-effectiveness, and flexibility make it a preferred choice for powering buildings and industrial setups.

The journey of busbar trunking systems reflects significant progress in electrical engineering, reshaping how electricity is distributed and utilized in modern infrastructure.

Types of Busbar Trunking Systems

Bus trunking and busbar trunking systems are crucial components of modern electrical distribution. They consist of metal bars called busbars housed within protective enclosures to ensure safe and reliable power distribution. Let’s explore the various types and applications of these systems.

For those in India seeking busbar trunking installation services, Manikaran provides reliable solutions tailored to your needs. Whether it’s for buildings or industrial setups, their expertise ensures efficient and safe installation of busbar trunking systems.

Manikaran offers comprehensive busbar trunking installation services in India, catering to diverse electrical distribution needs. Their expertise ensures seamless installation of busbar trunking systems, optimizing power distribution efficiency while prioritizing safety.

Types of Bus Trunking Systems:

Sandwich Bus Trunking (SB):

Ideal for heavy-duty industrial applications, SB features a robust design with busbars sandwiched between insulating layers, ensuring reliable power distribution in demanding environments.

Compact Air Bus Trunking (CB):

CB employs air as an insulating medium between busbars, resulting in a lightweight and compact design suitable for space-constrained areas or setups requiring frequent reconfigurations.

Lighting Trunking (LB) – Low Voltage (LV):

LB-LV systems are tailored for distributing low-voltage power to lighting fixtures in buildings, ensuring efficient power distribution while minimizing energy losses.

Track Busway (MB) LV:

MB-LV systems integrate power distribution with track systems for mounting electrical accessories, offering versatility in both power and data distribution for modern commercial and industrial environments.

Applications of Busbar Trunking System:

Industrial Facilities: Manikaran’s busbar trunking services cater to industries like manufacturing plants and power generation facilities, ensuring reliable distribution of high-power electrical loads to machinery and equipment.

Commercial Buildings: In office complexes, malls, and hotels, their services support seamless power distribution to lighting, HVAC systems, and other electrical loads, ensuring uninterrupted operations.

Data Centers: With high-density power distribution solutions, Manikaran enables efficient power distribution in data center environments, crucial for supporting extensive power demands of servers and networking equipment.

Transportation: Their expertise extends to transportation infrastructure, providing reliable power distribution for lighting, escalators, and other electrical systems in airports and railway stations, ensuring passenger safety and comfort.

Benefits of Bus Trunking Systems:

- Efficiency: Manikaran’s busbar trunking installation services enhance energy efficiency by minimizing power losses and ensuring uniform distribution.

- Flexibility: They offer flexible solutions easily reconfigured to accommodate changing electrical loads and layouts.

- Safety: Prioritizing safety, their installations feature robust enclosures and protective features to mitigate hazards such as electrical fires.

- Scalability: Manikaran’s services are scalable, allowing for easy expansion or modification to meet evolving power distribution needs, suitable for both new installations and retrofits.

In summary, Manikaran’s busbar trunking services play a pivotal role in modern electrical infrastructure, offering efficient, flexible, and reliable solutions for power distribution across various sectors and applications.

Manikaran offers professional busbar trunking installation services in India, ensuring efficient and safe power distribution in diverse settings. Their expertise covers various types of busbar trunking systems, each with specific capabilities, including current carrying capacities.

Sandwich Bus Trunking (SB):

Manikaran installs SB busbar trunking systems known for their robustness and high current carrying capacities. Ideal for heavy-duty industrial applications like manufacturing plants and power facilities, SB ensures reliable power distribution in demanding environments.

Compact Air Bus Trunking (CB):

Their CB busbar trunking services focus on installing systems with impressive current carrying capacities despite their compact design. CB is suitable for spaces with limitations or requiring flexible installation, such as commercial buildings and data centers.

Lighting Trunking (LB) – Low Voltage (LV):

Manikaran specializes in setting up LB-LV busbar trunking systems optimized for distributing low-voltage power to lighting fixtures. While LB-LV may have lower current carrying capacities, they excel in lighting applications, ensuring efficient power distribution with minimal energy losses in offices, retail spaces, and residential buildings.

Track Busway (MB) LV:

Their expertise extends to MB-LV busbar trunking systems, integrating power distribution with track systems for mounting lighting fixtures and accessories. These systems maintain robust current carrying capacities, suitable for various commercial and industrial environments, supporting modern technologies like smart building automation.

In conclusion, Manikaran’s busbar trunking installation services play a vital role in modern electrical infrastructure, providing efficient and reliable power distribution solutions across different applications and settings. Whether in heavy-duty industries or commercial buildings, they ensure the necessary current carrying capacities to meet diverse electrical load demands.

FAQs

Busbar trunking is an electrical power distribution system that utilizes enclosed metal bars, typically made of copper or aluminum, to conduct electricity throughout a building or facility. These bars, known as busbars, are housed in protective enclosures and carry electrical currents from the main power supply to various distribution points within the premises. Busbar trunking systems are modular in design, allowing for easy installation and expansion as needed. They are commonly used in commercial and industrial settings to efficiently distribute power to equipment, machinery, and lighting fixtures

A busbar is a metallic strip or bar used to distribute electrical power efficiently from a main source to multiple outlets or devices within an electrical system. It acts as a common connection point for various electrical circuits, allowing for the easy and secure distribution of electricity. Busbars are commonly used in switchboards, distribution boards, and other electrical enclosures to streamline the wiring process and reduce the need for individual wiring connections. They provide a more organized and space-efficient solution for managing complex electrical networks

Busbar trunking is preferred in factories due to several reasons:

- Efficiency: It provides a more efficient and reliable method of distributing power compared to traditional cable systems, reducing the risk of downtime and electrical failures.

- Flexibility: Busbar trunking systems offer flexibility in layout and configuration, allowing for easier adaptation to changing production requirements or facility layouts.

- Safety: Enclosed busbars minimize the risk of electrical hazards such as short circuits, electrical fires, and accidental contact, enhancing overall workplace safety

Busbar trunking systems offer several advantages:

- Cost Savings: They reduce installation time and labor costs compared to conventional cable systems, leading to overall cost savings.

- Flexibility: Busbar trunking systems can be easily modified or extended to accommodate changes in electrical loads or facility layouts.

- Space Efficiency: Enclosed busbars require less space than traditional cable systems, maximizing available floor space in factories and industrial facilities.

- Safety: Reduced risk of electrical faults, such as short circuits and overheating, enhances workplace safety for personnel and equipment.